SRCI over PROFINET

Standard Robot Command Interface

SRCI allows for efficient robot programming in a PLC engineering environment. Users can write a complete machine program, including robots, and thus integrate the robot program and operation into the machine (PLC). With over 115 robot functions offered by SRCI, the user can call these functions in the PLC while the robot controller reports the required robot state information back to the PLC .

Benefits

General:

- Meet the highly demanded customer requirement for standardization in and simplification of robotics

Robot manufacturer specific:

- Enable PLC experts to program robots via their familiar tool environment, thus opening up robotics to a new target group

- One single interpreter software that can be used cross-vendor for different PLCs

PLC manufacturer specific:

- Enable robot programming in a standardized fashion in PLC environment for PLC experts

- One single library that can be used for different robots of various brands and types

Implementation

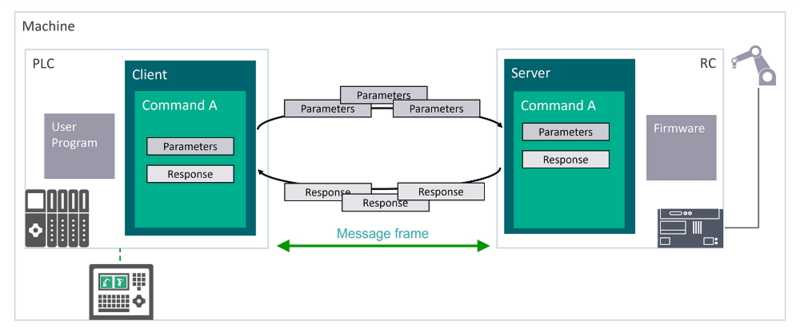

The interface between PLC and RC is based on a client-server model, implementing remote procedure call mechanisms. The PLC (client) invokes server functions by sending command messages and its corresponding arguments (parameters) to the RC (server). The RC executes the function and in turn sends back command-specific response messages.

The client has the task of sending commands to the server and receiving one or multiple responses. Arguments and responses of different commands may vary. Therefore, the client must update commands and send an updated argument list to the server. Likewise, the server sends multiple response messages to inform the client of the current function execution state (busy, active, done) and other response data.

The interface communication between PLC and RC can be realized via PROFINET (isochronous mode is not necessary), while the RC functions as IO-Device and the PLC as IO-Controller. However, the realization is also be possible on other common fieldbuses.